Products

Are You Looking For Carbon Brush For Motor?

CCB is a professional Carbon Products manufacturer for Carbon Brush, Carbon Vane,Carbon Seal,Carbon Bearing and other graphite products. Our products have been sold worldwide for a wide range of applications in auto, oil refining, chemical, marine, power generation and pipeline transportation and other industries.

REQUEST A QUOTE FOR MORE DETAILS

The Ultimate Guide Of Graphite Products

Carbon Brush Sizes, Types, Uses and More

Functions of a carbon brush

Chapter 1

Choices for Electrical Motors

Chapter 2

life time of the motor brush

Chapter 3

Carbon Vane in Vacuum Pump

Chapter 4

Carbon Graphite Seals

Chapter 5

Carbon Brush Holder

Chapter 6

Chapter 1

Request A Free Quote

We'd like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right valve you want.

- 0513 8976 8689

- sale@chinacarbonbrush.com

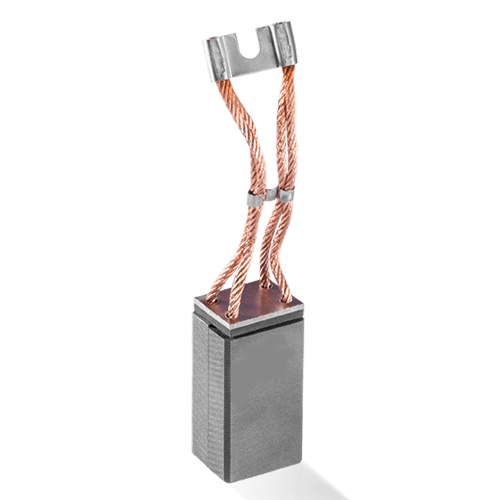

Functions of a carbon brush

A carbon brush is a critical part of a dc motor, which relies on the brush for the transmission of electrical current coming from the machine’s rotating part. The brush is also responsible for changing the course of current in the conductors during the rotation process. The carbon brush also ensures the commutation of the current’s direction several times per rotation of the machine.

Aside from these functions, the carbon brush keeps the surface of the slip ring, or the commutator, clean. Since these brushes have a protective carbon film, it ensures a close contact as the machine operates. Thus, this prevents the motor, or commutator, from wearing out. This barrier is why the commutator maintains its smoothness and optimal condition.

Carbon is the best material for these brushes. Carbon contains all the electrical, physical, and mechanical properties suitable for protecting the motor from damages.

Chapter 2

Carbon Brush Grade Choices for Electrical Motors

Carbon brushes are vital components used in various industries for electrical applications. They consist of a mixture of carbon and other conductive materials, which are designed to transfer electrical currents between stationary and rotating parts in machines and equipment. Here, I will provide you with a comprehensive overview of different types of carbon brushes and their applications.

Electrographitic Carbon Brushes

Strength and density distinguish electrographitic carbon motor brushes. This is due to the makeup of raw materials that go into making these brushes. The outcome is superior commutating ability, performance at high temperature/low humidity settings and as a result, longer life. Treatments can allow electrographitic materials to operate well in a variety of contaminated environments.

Graphite Carbon Brushes

Graphite carbon brushes are the most commonly used type. They are made from a combination of natural graphite and synthetic graphite materials. These brushes are ideal for low voltage and low current applications, such as in small motors, power tools, and household appliances.

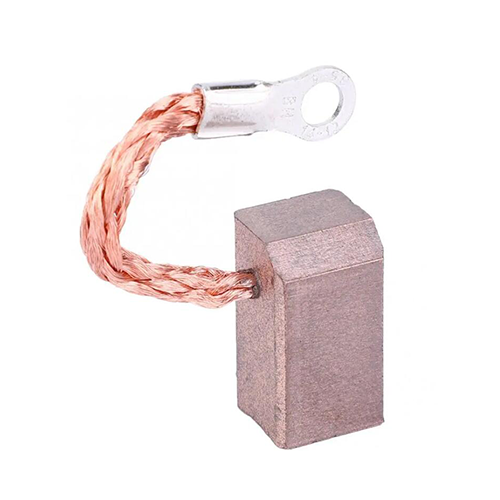

Metal Graphite Carbon Brushes

Metal graphite carbon brushes for electrical motors are often made from natural graphite and fine metal powders. Copper is the most common, but silver, tin and lead are sometimes used. Metal graphite brushes are ideal for many applications due to low resistivity. Metal graphite brushes are used on commutators of plating generators that have low voltage and high brush current densities. They operate on rings of wound rotor induction motors where high brush current densities are also found. Metal graphite brushes are used with grounding brushes because of their low contact drop.

Resin-Bonded Carbon Brushes

Resin-bonded carbon brushes are manufactured by combining graphite or electrographite with a resin binder. They are known for their low friction properties, making them suitable for delicate applications. These brushes are often used in precision instruments, such as medical devices, scientific equipment, and automotive sensors.

In summary, carbon brushes are available in different variations to meet the specific requirements of diverse applications. The choice of carbon brush type depends on factors such as current and voltage levels, temperature, and operating conditions. Whether it’s for small household appliances or heavy-duty industrial machinery, carbon brushes play a crucial role in enabling the smooth and efficient transfer of electrical energy.

Chapter 3

How Long Do Carbon Brushes Last in Power Tools?

How long do carbon brushes last?

Carbon brushes will on average last between 1 and 5 years in most power tools but this is all dependant on how much they are used in number of hours, the more daily use the power tool has the quicker it will wear over a certain period of time.

Some brushes can last longer than others all depending on the power of the tool (aka how much wear it puts through the brushes per use). High AH battery powered cordless tools can wear the brushes away really quickly.

On a side note, as the battery technology changes, many cordless tools are changing to brushless formats to combat the need to change parts so regularly.

Signs of Wearing Carbon Brushes

The classic signs your brushes are ready to be replaced are:

- More Sparks Than Usual – a little sparking is normal, but if it’s gradually getting worse then it is a sign of excessive wearing of brushes.

- Drops in Performance – if the tool is losing RPM and general performance, then it’s a sign of the carbon brushes wearing out.

- Burning Smell – Caused by arcing or flashing could be a sign of brushes not fitted correctly, excessive brush wear damaged or dirty commutator. There are different types of smells that can also indicate other underlying issues with armatures and winding insulations which all leave distinctive smells. In any case you should stop using the power tool immediately and seek professional advice from a repair technician to diagnose exact cause.

Why are Carbon Brushes Important?

Carbon brushes play an important role in the transfer of current from the static part fo the moving part of an electrical motor, helping to transfer energy into the moving part of a power tool.

A damaged or poorly functioning carbon brush can reduce the performance of your tool.

What Impacts the Lifespan of a Carbon Brush?

Different factors can impact the lifespan of your tools carbon brush:

- Brush material – the type and quality of the materials used in your carbon brush can impact the lifespan, so use a high quality brush made from carbon and graphite.

- Brush grade – choose the grade of brush that’s appropriate for your power tool, to ensure it’s designed to be used for that motor speed/load.

- Operating conditions – high speeds, high load, and harsh environments can all increase the wear on carbon brushes.

- Maintenance practices – regular tool maintenance, cleaning, and inspection can help to identify issues early and prevent wear.

Chapter 4

Carbon Vane In Vacuum Pump

Carbon vanes are essential components used in various industries for vacuum pump applications. They are made from high-quality carbon graphite material and are designed to provide reliable performance and durability in demanding environments. In this article, I will provide you with a comprehensive overview of carbon vanes, including their features, performance characteristics, and applications.

Features of Carbon Vanes:

- High Wear Resistance: Carbon vanes exhibit exceptional wear resistance, allowing them to withstand the friction and heat generated during operation. This attribute ensures a longer service life and reduces the need for frequent replacements.

- Self-Lubricating Properties: Carbon vanes possess self-lubricating properties, which minimize the need for additional lubricants and improve the overall efficiency of vacuum pumps. This attribute also reduces maintenance requirements and enhances system reliability.

- Chemical and Corrosion Resistance: Carbon vanes are highly resistant to various chemicals and corrosive substances, making them suitable for applications where exposure to aggressive fluids is common. This resistance ensures the longevity and performance of the vanes in challenging operating conditions.

Performance Characteristics of Carbon Vanes:

- Excellent Thermal Conductivity: Carbon vanes have excellent thermal conductivity properties, allowing them to dissipate heat effectively during operation. This characteristic prevents overheating and maintains optimal performance levels, even in high-temperature environments.

- Low Friction Coefficient: Carbon vanes offer low friction coefficients when in contact with other surfaces. This feature reduces energy consumption, enhances efficiency, and ensures smooth operation of vacuum pump systems.

- High Mechanical Strength: Carbon vanes exhibit high mechanical strength, enabling them to withstand the mechanical stress and pressure differentials experienced during operation. This strength ensures the vanes can effectively create a vacuum by sealing the pump chambers.

Applications of Carbon Vanes:

- Industrial Vacuum Pumps: Carbon vanes are extensively used in various industrial vacuum pump applications, including rotary vane vacuum pumps, dry screw vacuum pumps, and oil-sealed rotary vane vacuum pumps. These pumps are employed in industries such as packaging, printing, plastics, woodworking, and food processing.

- Automotive Industry: Carbon vanes are utilized in automotive applications, particularly in vacuum-assisted braking systems. They help to create the required vacuum for efficient braking by sealing the vacuum pump chambers.

- Medical and Laboratory Equipment: Carbon vanes find applications in medical and laboratory equipment, including vacuum filtration systems, freeze dryers, and vacuum ovens. Their excellent chemical resistance and reliability make them ideal for maintaining a clean and sterile environment.

- Environmental Applications: Carbon vanes are used in environmental applications, such as wastewater treatment plants and air pollution control systems. They help create a vacuum for the efficient operation of these systems, ensuring proper treatment and control of pollutants.

In conclusion, carbon vanes are versatile components that play a vital role in vacuum pump applications across various industries. Their exceptional wear resistance, self-lubricating properties, and resistance to chemicals make them suitable for demanding operating conditions. With their excellent performance characteristics and reliability, carbon vanes contribute to the efficient operation of vacuum systems in industrial, automotive, medical, and environmental applications.

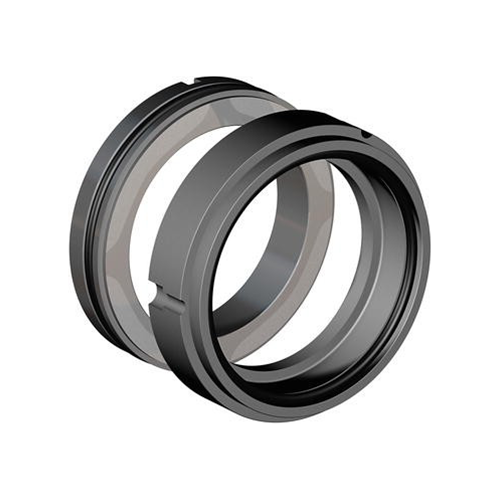

Chapter 5

Carbon Graphite Seals

We provide premium-quality, after-market carbon ring shaft seals, graphite bushings, and other parts made to exacting standards found in OEM parts. We also make economical, custom parts for machines that have been modified. Our high-performance replacement parts can help maximize the productivity of older, out-of-warranty machines to keep them in service longer. No matter how old your machine is, we can make and stock parts for it.

If you need to improve operating life or modify design parameters to increase efficiency and to meet environmental standards, we can help. We have seen and solved countless seal and bearing problems involving a wide variety of rotating equipment in all kinds of service and operating environments. Many times these problems are solved with our upgraded parts that are superior to standard OEM replacement parts.

Carbon carbon/ graphite seals and bearings are used where extreme operating temperatures and/or corrosive fluids would cause conventional lubricants to decompose, where lubricants would contaminate process fluids, and where equipment design makes conventional lubricating systems too expensive to install and maintain. Non-lubricating applications for which CCB Carbon supplies carbon/graphite grades include electrodes and brazing boats, jigs, and fixtures.

Carbon/Graphite Materials

Carbon/graphite grades are chosen to be compatible with the fluids being handled and with the mating seal surfaces. Typical carbon grades used are carbon/graphite with resin impregnation, and Shore Scleroscope hardnesses that range from 77 to 100. For operating temperatures above 500° F, metal-impregnated carbon/graphite is used. The metal also has the appropriate corrosion resistance for the intended service.

Precision Manufacturing

Seal geometry is extremely important to service life. The two seal faces must be accurately machined so that the seal rotates at a one-half speed relative to the rotating seal ring, subjecting both seal faces to the same wear rate. If not identical, one seal face will wear excessively, shortening seal life.

Our seal surfaces are lapped and polished to as flat as 1 helium light band (less than 12 millionths of an inch) for optimum sealing performance. Precise machining also produces perfectly round seals, preventing vibration that causes premature seal failure.

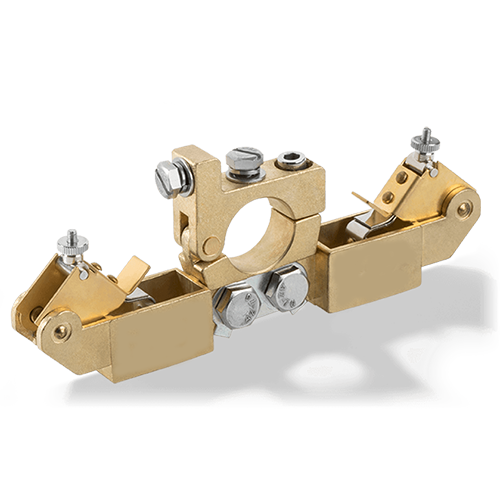

Chapter 6

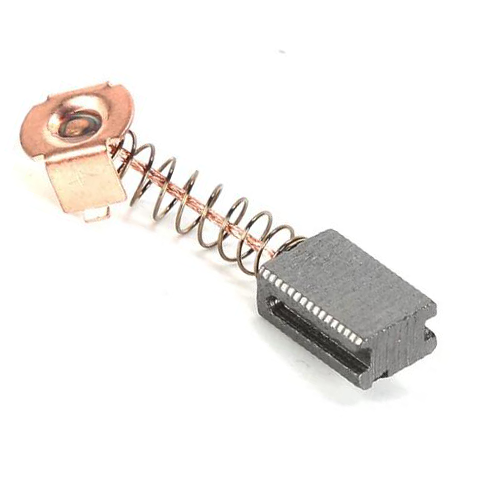

Carbon Brush Holder

Carbon brush holders are crucial components used in electrical machinery and equipment to hold carbon brushes securely in place and facilitate their proper functioning. They play a vital role in ensuring the efficient transfer of electrical current between stationary and rotating parts. In this article, I will provide you with a comprehensive overview of carbon brush holders, including their features, performance characteristics, and applications.

Features of Carbon Brush Holders:

- Material and Construction: Carbon brush holders are typically made from high-quality materials such as metal or plastic. They are designed to provide mechanical support and maintain the position of the carbon brushes during operation. The construction of the holders ensures stability and durability in various environments.

- Spring Mechanism: Many carbon brush holders feature a spring mechanism that maintains constant pressure between the brushes and the commutator or slip rings. This mechanism ensures proper contact and minimizes the risk of arcing or sparking during operation.

- Easy Installation and Replacement: Carbon brush holders are designed for easy installation and replacement. They often have a simple and user-friendly design, allowing for quick and convenient maintenance of electrical machines and equipment.

Performance Characteristics of Carbon Brush Holders:

- Electrical Conductivity: Carbon brush holders are designed to provide excellent electrical conductivity between the brushes and the rotating parts. They ensure a stable and reliable transfer of electrical current, minimizing energy loss and maximizing the efficiency of the system.

- Vibration Damping: Carbon brush holders can absorb vibrations generated during operation, reducing the stress on the brushes and improving their longevity. This characteristic helps to maintain a consistent and stable connection between the brushes and the rotating parts.

- Heat Dissipation: Carbon brush holders often incorporate heat dissipation features to prevent overheating. They help to dissipate heat generated by the electrical current, ensuring the brushes and the holder remain within the optimal temperature range for efficient operation.

Applications of Carbon Brush Holders:

- Electric Motors and Generators: Carbon brush holders are extensively used in electric motors and generators, where they hold the carbon brushes in place and facilitate the transfer of electrical current between the stationary and rotating parts. They are commonly found in various motor types, including DC motors and AC generators.

- Alternators and Starter Motors: Carbon brush holders are employed in alternators and starter motors, which are critical components in automotive applications. They ensure proper contact between the brushes and the rotating parts to enable the generation of electricity or initiate the engine’s cranking process.

- Industrial Machinery: Carbon brush holders find applications in various industrial machinery, such as machine tools, pumps, and compressors. They provide the necessary support and electrical conductivity for efficient and reliable operation in demanding industrial environments.

- Wind Turbines: Carbon brush holders are used in wind turbines to hold and maintain the position of the carbon brushes in the generator. They ensure a consistent flow of electricity from the rotating blades to the power grid.

In summary, carbon brush holders are essential components that contribute to the efficient and reliable operation of electrical machinery and equipment. Their features, performance characteristics, and ease of installation make them indispensable in various applications, including electric motors, generators, automotive systems,

In Summary

The wide carbon graphite products can overwhelm the buyer. However, if equipped with the right industrial information, decision making becomes much easier. Our main products are the carbon brushes for motor, carbon vane for vacuum pump, carbon graphite seals and carbon brush holders. If you need them, pls contact with us.

Request A Free Quote

We'd like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right valve you want.

- 0513 8976 8689

- sale@chinacarbonbrush.com